Content

(a click to the sub-title leads to the article section)

- Frame

Conditions

- Energy

Requirements

- Mission and

Goals of the Energy Concept

- Actions and

Solutions

-

- Capital

Expenditure

- Block

Diagram

1. Frame Conditions

- Open alpine association hut of category I, new building, low

energy house, special wooden construction

- 31 beds; 60 mattresses; 90 seats for dining in 2

rooms

- about 4000 accomodation-guests per year; 10.000

day-visistors

- open from may until november, through new years eve, and on

easter (sum about 204 days)

- material transport on a forrest-road (11km), further via

ropeway (max. 150kg netto, abt. 250m height)

- way-connections to Bad Tölz, Benediktbeuern, Jachenau,

Lenggries, Kochel, Walchensee

- from the end of the forrest-road access to the hut only by feed

on a winding path

2. Energy Requirements

Based on the operation of the old hut we have known the

experienced data of the "direct" energy consumers, f.i. ropeway

operation, water pump, lighting system, cooking and washing.

heating was mostly in the area of the hutkeeper with the woodstove

of the kitchen (it was also used to produce a little amount of hot

water for the kitchen and personnel). The two tiled stoves in the

dayroom (the only heating sources of the old hut) had been used not

often and not sufficiently. For cooking also liquid gas was

used.

The "indirect" energy consumption of the hut in the environment had

been about 1700 liters of fuel ( f.i. for the daily one, mostly two

transports of personnel from Benediktbeuern to the base station of

the ropeway, the daily supply rides of the hutkeeper for fresh

food, the weekly supply rides for the delivery of drinks - cooled

and in bottles).

Hypothesis: 23 km forrest road and 500m height per ride.

The direct and indirect energy requirement of the old hut were used

as a base for the planning of a new ecological overall concept of

the new hut and also for a new energy concept.

The daily energy requirements has been 40 kWh electrically and 90

kWh thermically.

3. Mission and Goals of the Energy Concept

- Arguments of an optimum economy and minimum capital expenditure

must not get highest priority although economy and ecology should

be estimated equal.

- Highest possible reduction of the overall emissions from the

operation of the hut during summer and winter, ( supply rides,

personnel rides, noise, exhaust fumes, waste water)

- Exact regard of a lawfulness Operation of the hut

- Full comfort of the hut and a sufficient offer of accomodation,

food and drinks by intelligent solutions

- Temporary heating through the opening period when temerature is

low, weather is bad, at night and when from september on the hut

lies in the shadow of the northern wall

- Sufficient cooling of the depots of fresh food (safe against

vermin) and sale of drinks primarily based on big containers

- Block-heating-generator, capable of automated starting, with

ecologically beneficial fuel, independant of personnel

- 100% exploitation of the motor-heat for the thermal energy

requirement of the hut; no emergency cooling at normal

operation

- Low budget operation, also during the hut-closing at

wintertime

- Low service requirements by robust, simple individual devices

of the energy supply

- Safe possibilities for replacement of individual devices at the

end of lifetime

- Reliable redundancy of the devices

4. Actions and Solutions

During longlasting model-calculations specialists have together

experienced the theoretically best way of solutions. Because of the

additionally necessary requirements the overall energy requirements

rarely can be reduced, but will be shifted more to the direct

energy requirements. The produced energy will be optimally used

with the latest state of the art.

The usable power for

the hut has been doubled to times before. The pollution could be

reduced to 30 percent compared to the installations before (in

spite of increasing the power!).

Destruction of environment by transports of dangerous goods will

be avoided.

The success of the new energy concept will be fully reached first

after all included people have changed their working procedures and

loved habits, which mostly were aimed to economy, to the goals of a

ecologically beneficial hut operation.

4.1 Reduction of Energy Consumption

Based on the actual conditions, carefully was checked which

energy consumer could be avoided because alternative possibilities

exist. With the operation concept of the Tutzinger Hütte the

result shows the following picture:

Avoidable Consumer of electric current

| Device |

Remark |

| Coffee percolator |

Hotel infusion device with cooked water from the gas stove |

| Microwave |

With fresh food and corresponding menue not necessary |

| washer, dryer, iron pressing |

Light sleeping bag mandatory; rest laundry ecologically

beneficial finished down in the valley |

| Electric refrigerators |

Gas driven refrigerators because gas directly and low priced

available |

| Electric heating |

Underfloor heating driven by BHKW and wood stoves in the side

building or self-supplier-room |

| Electric cooker |

Gas stove |

| Electric boiler |

Hot water from warm water container; cooked water from gas

stove |

| Dish washer with heating |

Hot water from warm-water-container which is fed by the

block-heating-generator (BHKW) |

Necessary Consumer of electric current

| Device |

Consumption |

Remark |

| Ropeway |

1 to 4 kWh three phase current |

about 4 rides daily |

| Drinking water pump |

2 x 0.4 kWh three phase current |

|

| Degermination |

0,72 kWh / day |

|

| Refrigeration engineering |

3 x 0,7 kW three phase current |

1 of 3 alternating,

14 hours daily |

| Heating/Warmwater |

0,3 kW |

steady power |

| Dedector 110 V DC |

3,85 kWh at 35 A |

during loading phase, Rest for consumer |

3 Phase inverse rectifier, light, telephone converter,

smoke alarm, rescue guard, emergency illumination |

0,3 kW |

base consumption |

| Vacuum cleaner |

0,9 kWh |

|

| Dung water pump |

2 kWh Drehstrom |

1 x yearly at season end |

| Ventilator (kitchen), small kitchen devices |

0,3 - 0,5 kW |

when necessary at intense activity 2 hours |

| Hotwater dishwasher |

0.3 kW three phase current |

at intense activity ca. 2 hours per day |

4.2 Procedure with the draw-up of the energy

concept

- Together with the hutkeeper an operation concept for the hut

was developed. Daily returning activities are organized in a time

table with optimized course of the work so that saving of energy

and other ecological aspects are especially considered.

- All data for planning based on

-

- experienced

values

- the changed

operation data and

- the

recommendations of the producers

- had been carefully

estimated and considered in dimensioning for the

overall energy concept with sufficient reserves.

- With all used devices the operation was discussed in details

and and the preconditions of the producer were fulfilled

- Use of simple commercial industrial devices with service and

spareparts supply from the near areas. Easy maintenance, ruggedness

and simplicity of the modules instead of high efficiency based on

electronics are preferred. If possible electronics was

avoided.

- Planning of equal distribution of the consumers to the 3

phases; destination of priorities based on importance; operation of

the generator if possible under full power.

- Precaution measures for the circuits that none "undesired"

consumers could be switched to the net.

- Reception, documentation and evaluation of all important

consumers by counters for time and power in the individual

cables.

- For most important functions spare systems are available (

emergency generator, tiled stove, spare detector,

gas-heating-device, 3 stoves for wood or coal, 1 cooker for

bottle-gas)

- All installations were done by special firms which also got the

missions for professionel yearly maintenance

4.3 Components of the Energy Concept

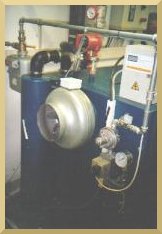

block heating generator,

backside

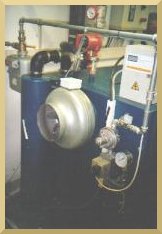

block heating generator,

frontside

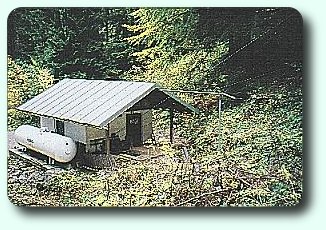

base station ropeway

gas tank and gase hose cognizable

- Primary energy/gas supply; Propan liquid gas (LPG), 6400 Liter

gastank at the base station (1100 m), Refill by regular tank car

via forrest road, hut supply via gas-pipe`` DN 20, NP 100, length

abt. 600 meter and height abt.250 m, fixing by steelrope on ropeway

supporter, prepressure steering 500 - 700 mbar, endpressure

steering at the hut for kitchen and BHKW

- Block-heating-generator (BHKW) from firm EAW in Westenfeld, 230

/ 400 V three phase current, Synchrongenerator, power abt. 7,5 kVA

electrical and 18 kW thermal, Ford 4 cylinder ottomotor with vacuum

operated control; for low noise fixed on dam-felt, noise 60 dBA,

operation with propangas (max. 50 min. 30 mB), warmth exchanger

with condensate trap/ -outflow, 24 V generator for starting battery

(automated starting) and regulation-tension, additional power

supply, potentialfree trouble report , Stamford three phase current

synchrongenerator, condensate pump, 70 mm plastic waste gas

pipe

- warmth store (abt. 500 kW) 2 layer store tank a 3800 Liter

store 100% of thermal energy of the electric current production for

alternating use during operation of the hut

- industrial batteries OPZS 48Volt DC, 1200 Ah load, for the

storing of redundant electric energy (for later use).

4.4 Mechanism of the Energy Supply System

Akku-Batterie 48 V

Photovoltaik on the roof

- The newly installed system has 3 bidirectional invers rectifier

at a 48V71200Ah battery block (accumulators). They are such

synchronized to build a 3-phases current net at the hut. 4.5 kWp

are permanently possible. Based on a certain level the block

heating generator or/and the diesel generator will be added to the

system.

- The inverse rectifier are such tuned that the block heating

generator will be operated with best efficiency. If more energy is

neccessary as the block heating generator can deliver, the inverse

rectifier will add energy from the battery block. Is the energy

demand less then the battery block will be loaded.

- All components can also be manually operated by the hut warden.

The components are switched and wired so that each can supply the

hut independantly from others.

- All components are industry standard, not special devices. A

photovoltaic device on the huts roof supports the block heating

generator. It is most valuable in wintertime. Its power is

sufficient to maintain the battery block without the necessity of

operating the block heating generator.

5. Capital Expenditure

Only for a part of the necessary activities frame-contracts

could be fixed. Individual contracts were made f.i. for brickwork

for the gas pipe ( base for the gas tank, ropefixing, a.s.o.),

shifting of the switchboards, increasing of the control

ingeneering, service works and some smaller additions. Especially

proplematic was to keep in order the parallel operation of the

supply engineering (ropeway, drinking water, electric power)

without break.

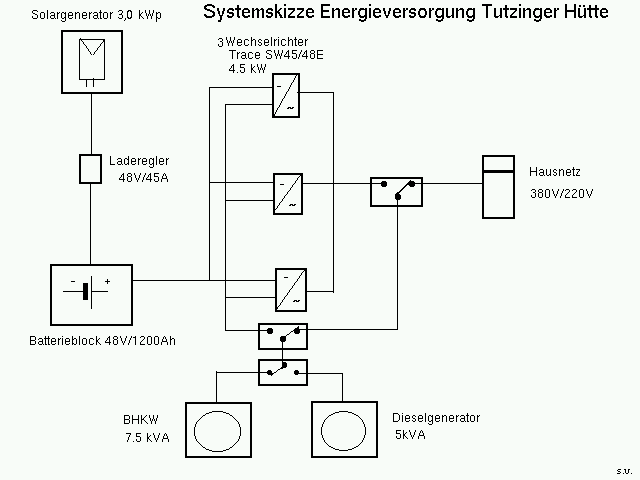

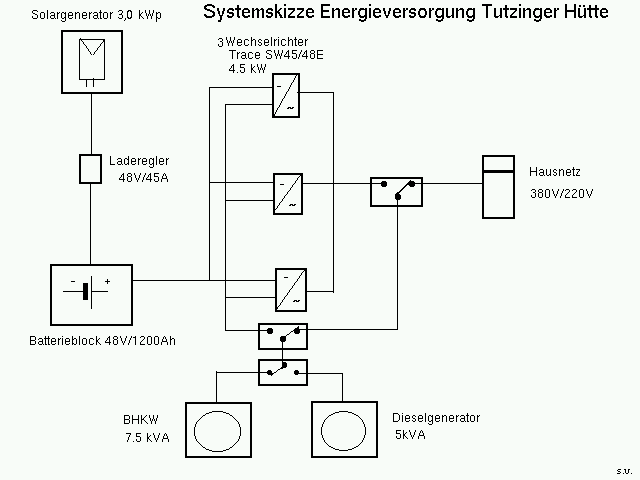

6. Block Diagram of the Energy Supply

Draft: Ingenieurbüro Dipl.-Ing.

Phys. Michael Berger, Garmisch-Partenkirchen

Drawing: Ulf Schreglmann